SECTION 2.1

Details of the end-to-end sustainable

waste management model

The Waste No More programme

Xynteo Vikaasa in collaboration with Hindustan Unilever and SBI Foundation, has conceptualized the ‘Waste No More’ Programme to solve the plastics waste management problem and support the Government of India’s Clean India Mission by establishing working models on plastic waste circularity. Our work focuses on building Islands of Excellence by:

1. Strengthening the waste management infrastructure,

2. Integrating the informal sector,

3. Educating and empowering communities and children and

4. Strengthening the ecosystem by informing policy.

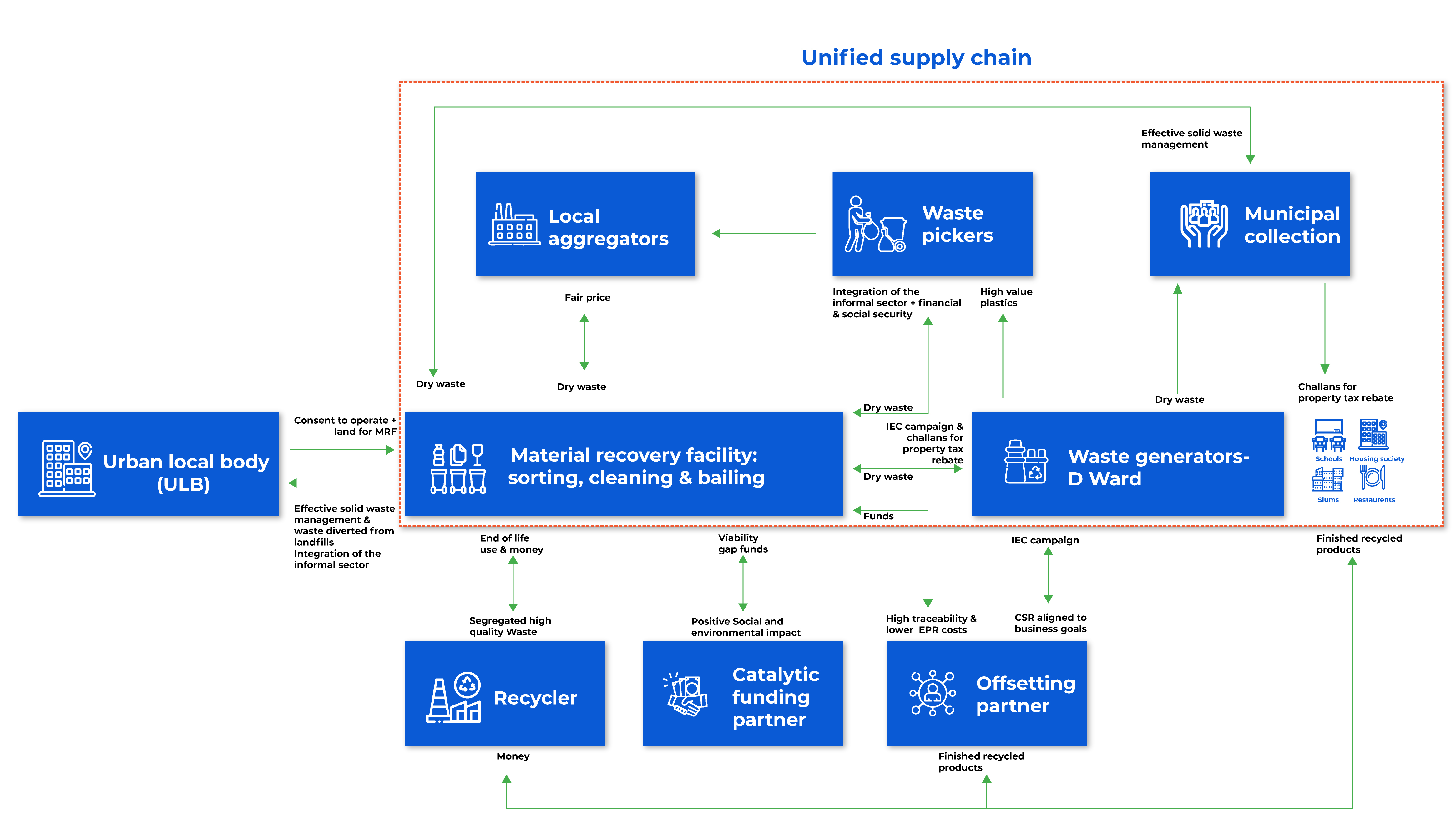

Waste No More Programme is a collaborative, sustainable business model implemented at the zonal (ward) level that works across the full waste value chain by building an inclusive circular economy.

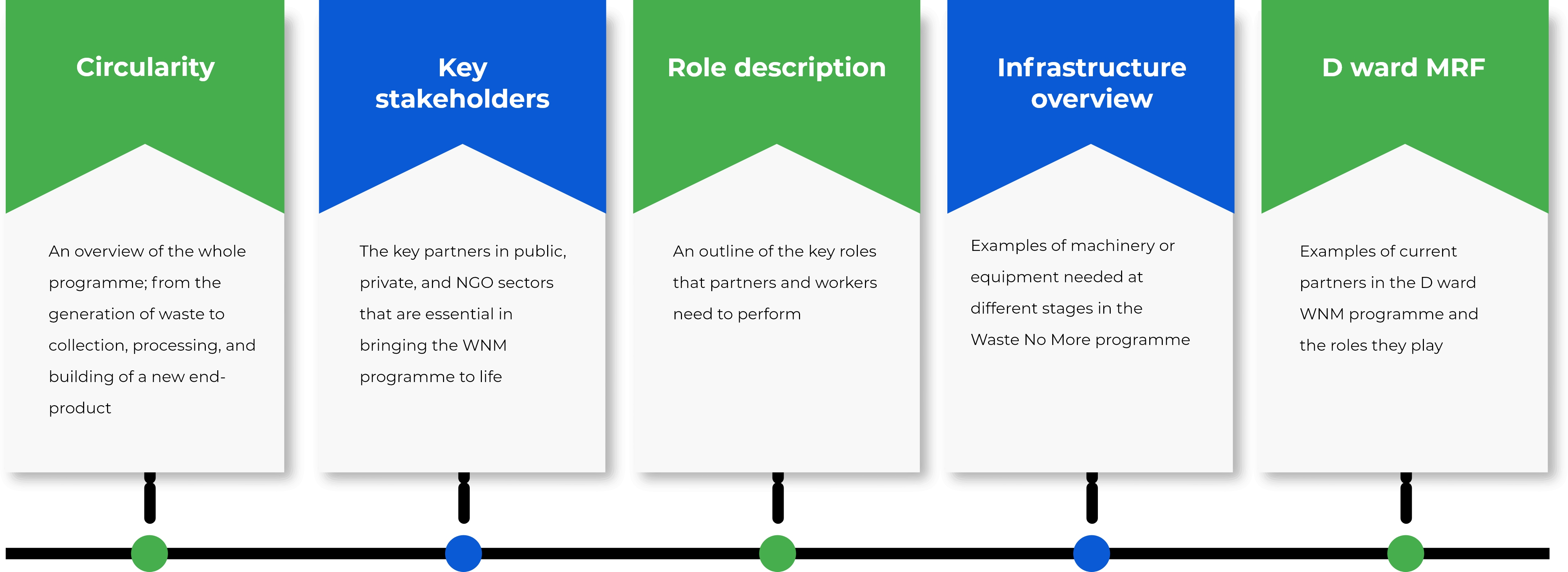

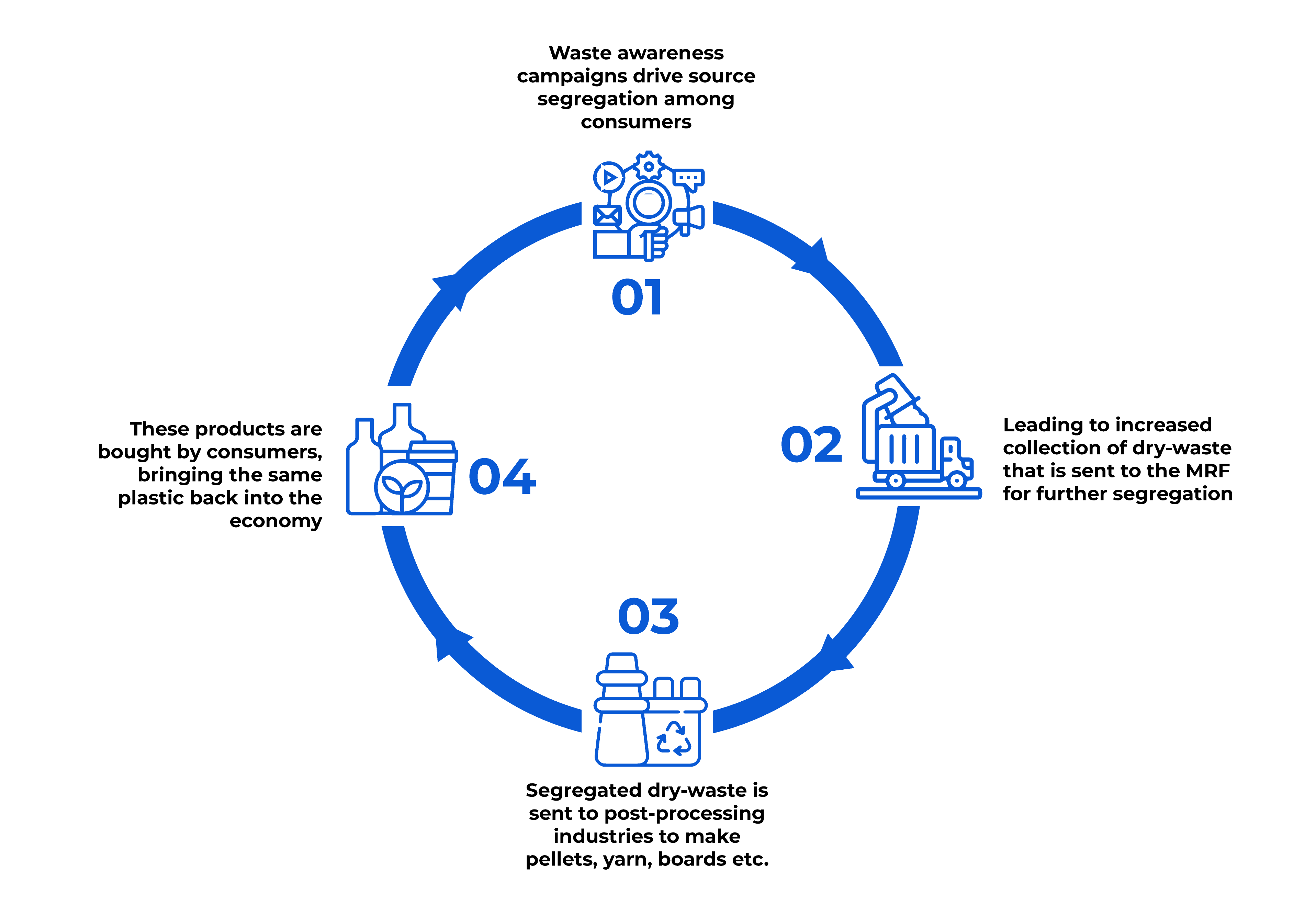

All the focus areas essentially converge into an end-to-end circular waste management model that flows in a four steps process in a repeat cycle:

SECTION 2.2

Case study D Ward MRF

An end-to-end waste management model

Project overview

- The end-to-end waste management model has been created in collaboration with MCGM, HUL and SBIF

- dry material recovery facility (MRF) has been set up in the local area to streamline secondary segregation and aid processing. The processed waste is being passed on to recyclers or businesses that produce new products such as notebooks from recycled paper, t-shirts from plastic fibres and plastic wood for furniture

- Existing informal sector has been integrated into the model to ensure fair wages and sustained livelihood to them

- Various behavioral change programmes have been launched in the area for school children and resident communities to increase waste segregation at sources

- SBI and HUL have also generate demand for the new, circular products that created from the recycled dry waste boosting the circular economy.

Project outcome

Key partners

Approval authority, provision of

MRF premises

Behavioral change expert and offsetting partner i.e. paying for plastic to be disposed sustainably

Recycler, D ward MRF

implementation partner

Approval authority, provision of MRF premises

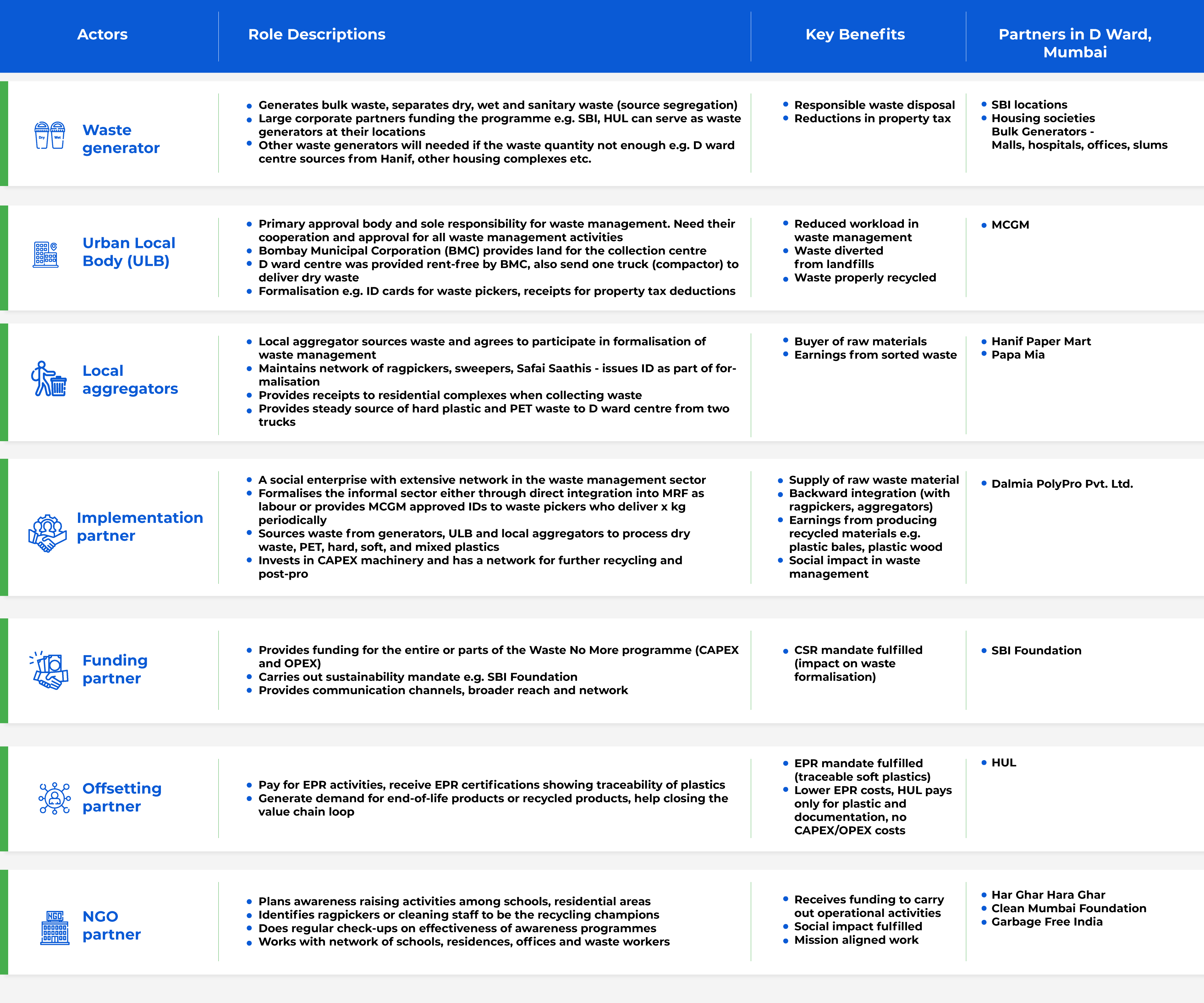

The WNM model includes building an inclusive circular economy by setting up adequate infrastructure, redefining partnerships, establishing connections with the informal sector, creating traceability and empowering communities

Island of excellence – end to end dry waste management

An inclusive, circular approach to waste management

Building an island of excellence – D ward

- A sustainable business model in end-to-end waste management

- Increased traceability and reduced cost of EPRs

- Inclusion of informal sector – employment and livelihood

- Increased segregation at source through awareness campaigns

- Waste diverted from landfills, with a potential across Mumbai and India

- Close the Loop

- Prevention - educating tomorrow’s consumers

D ward impact snapshot

4MT/day

of dry waste from D ward processed at MRF

1.5 Lakh

Residents

20

Schools

20

Commercial institutions

100+

Residential communities

100+

Safai-saathis and local waste aggregators

D ward MRF - FAQs

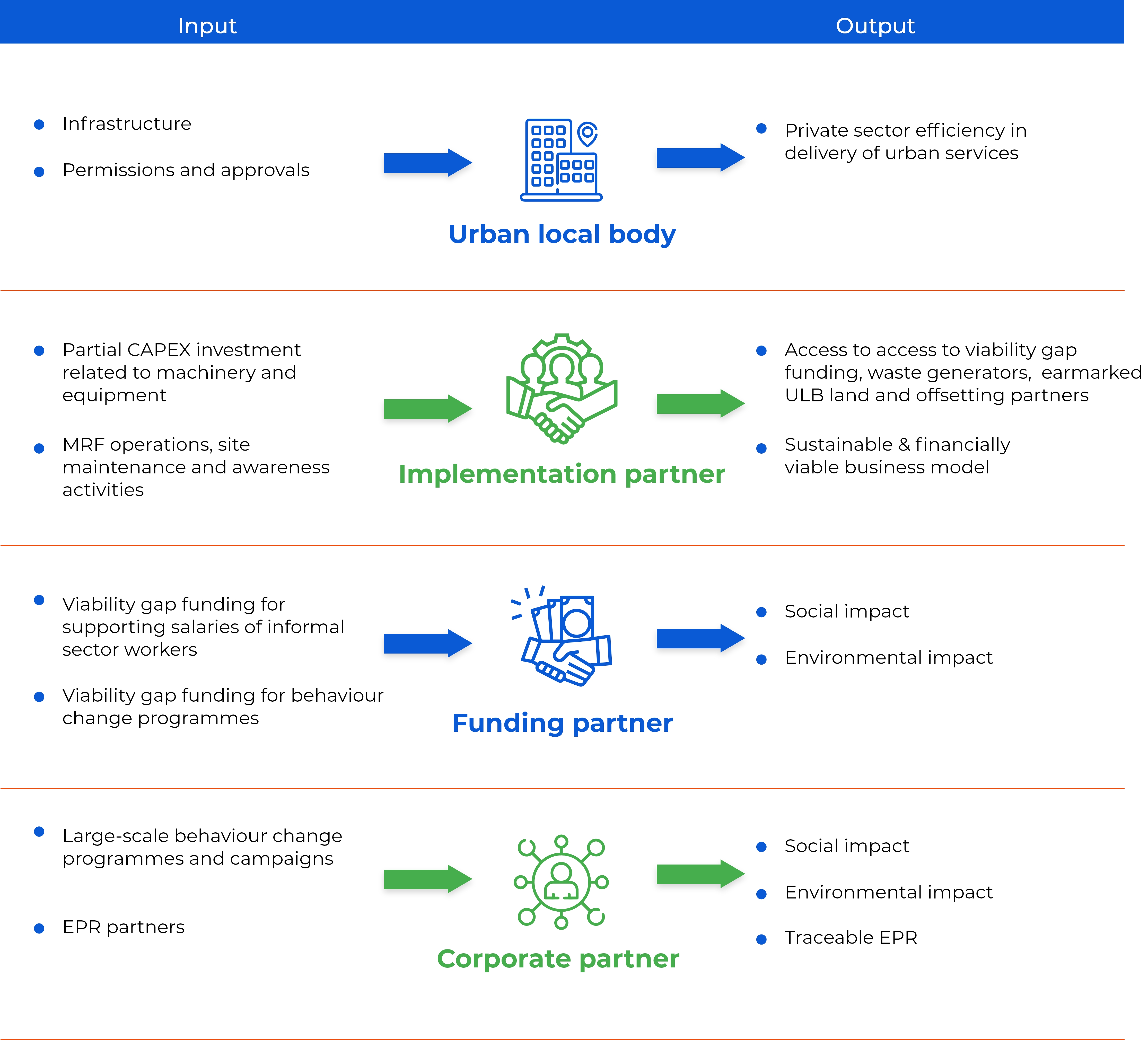

- Most ULBs have pre-identified land allotted for waste management, based on proposals this land is allocated and also supported with civil, mechanical, and electrical infrastructure

- Permission are required from ULBs to lease land for long-term use for the MRF

- With catalytic funding from SBIF, OPEX was paid for MRF has 8 people working, key roles include:

- Site Supervisor: Responsible for overall operations, maintains documentation and day-to-day handling, responsible for stakeholder coordination

- Collection Executive: Responsible for managing overall dry waste collection from aggregators and community, responsible for labour

- 6-8 safai-saathis working directly at the centre and 50+ are integrated for a unified supply chain

Approximately Inr 2 million funded by Implementation Partner (Dalmia PolyPro)

Approvals to run the center was provided by the ULB

Segregation conveyor, Jhatka Machine, Bail Press

NOTE: Based on land received machinery and capacity can be determined

Majority of dry waste is collected by local aggregators; & going ahead the dry waste would also be collected from bulk generators

Waste collection, manual sorting of dry waste, secondary segregation, bailing of sorted materials for further transport to recycling plants- MRF capacity prior to lockdown (COVID-19) was reached at 1.3 TPD

- MRF capacity of 3-4 TPD achieved

- Daily Records are maintained of incoming waste and outgoing segregated waste. Weekly records to be shared with the other stakeholders

SECTION 2.3

Business case for sustainable

waste management model

SECTION 2.4

Impact Case for sustainable

waste management model

Environment impact

The majority of dry waste is made up of plastic. It is either dumped in landfill or incinerated. This is both financially and environmentally unsustainable.

Air, land and water pollution

Health hazards for animals and human beings

Resource depletion

Diversion of waste from landfills and oceans along with open burning of waste.

Limits resource depletion as less virgin plastic and materials will be used for products. It also reduces the amount of energy it takes to procure or produce these raw materials.

Potential impact from the WTV programme:

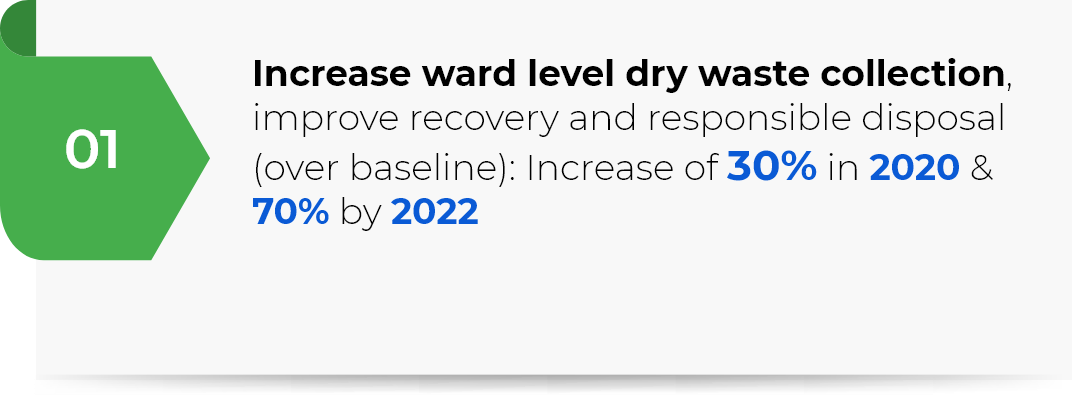

- The WTV programme will increase ward level dry waste collection, improving recovery and responsible disposal. This will significantly divert waste from landfills and oceans, preventing the above negative impacts.

- Recycling dry waste will also help limit resource depletion as less virgin plastic and materials will be used for products. It also reduces the amount of energy it takes to mine or produce these raw materials

Assessment metrics

Social impact

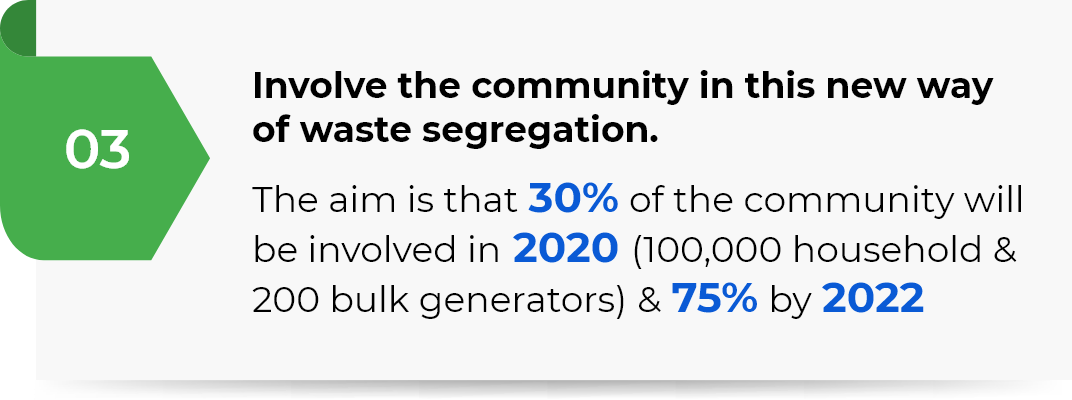

The informal waste sector in India is made up of the local aggregators (kabaadi system) and waste pickers and plays a significant role in collection and processing of recyclable material. To create a sustainable WNM model, it’s essential to recognise, identify and integrate informal sector workers into the formal waste management processes and initiatives.

Informal employment and low wages

Low dignified livelihood

Unhygienic working conditions

Short-term welfare (protective gear, facilities, care, housing, etc.)

Medium-term development opportunities (education, alternative vocational training, income generation)

Long-term rights (awareness raising, labour standards, legal reform and enforcement)